ebm-papst has launched AxiBlade, a new generation of optimized axial fans.

The purpose through this handout is a brief comparison with bringing some technical specifications from below models of ebm-papst’s fans:

(8317078523)(VWA0800B7SNZ ( W6D800KG1301

- A6D800AD0101I(W6D800GD0125)

The advantages of AxiBlade at a Glance:

1. Optimum efficiency of up to 38.53% while HyBlade is equivalent to 33.35%(15%)

Through curve 2, it’s considerable.

It means:

Every engineer and fan designer knows about how challenging it can be to raise 1 unit in efficiency term and the long way to achieve, so use this 5-unit boost (33.35% to 38.5%) at ease.

2. A noise reduction through fan’s installation inside the unit

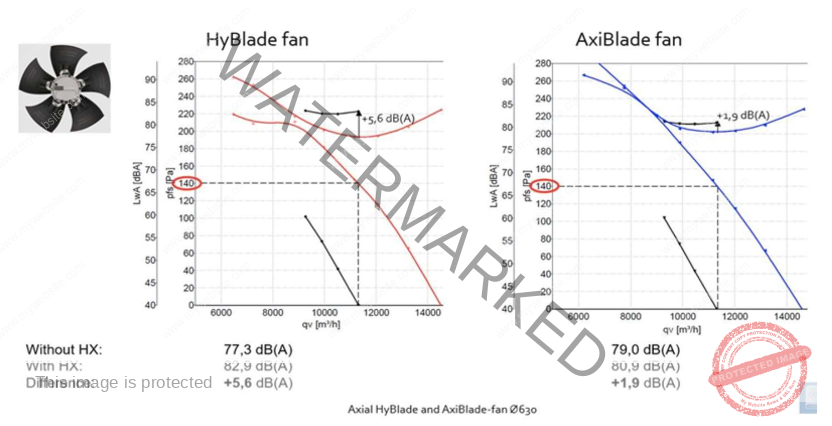

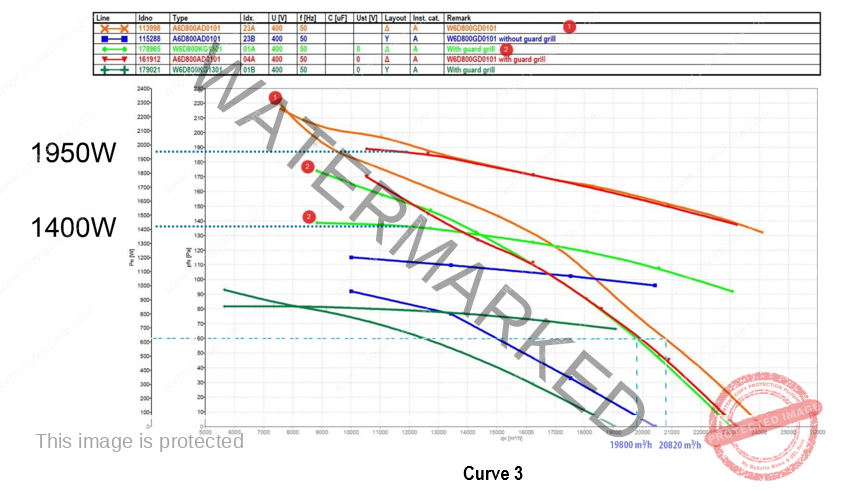

Through curve 3:

AxiBlade’s Noise level inside the unit: 80.9 dB

HyBlade’s Noise level inside the unit: 82.9 dB

It means:

Due to aerodynamical performance of the Axiblade impeller noise levels will not increase as high as with the HyBlade fans once built into a unit.

Although it is true that Noise level outside the unit for Axiblade is higher than HyBlade, just see the results after installation the AxiBlade inside a unit; AxiBlade shows lower Noise level(80.9 dB(A) vs 82.9 dB(A))

Note: the real operational situation is the mounting condition.

curve2

3. No requirement for AxiTop, due to lower noise with Axiblade

It means:

Omitting the requirement for AxiTop leads to less costs, another benefit of AxiBlade

4. 30% less energy consumption

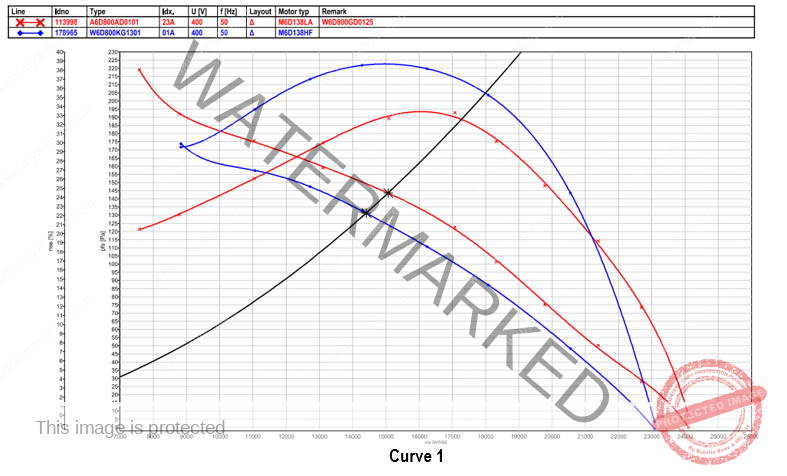

Through curve 1:

HyBlade consumption: 1950 W

AxiBlade consumption: 1400 W

(AxiBlade consumes up to 550 W less energy), (30%)

Given a unit with 2 or 3 fans, this difference shows itself more (3*550, 1650 W for a unit)

It means:

less costs for providing electronic parts as VSD and less energy costs.

5. Volume rate change

The difference is 3%, AxiBlade’s air flow is less than HyBlade

Comparing 4 above facts:

- Any low powered motor doesn’t imply a weakness in a system

An engineering design tends to gain a low energy consumption within an operating point

It can be seen that manufacturers don’t work on maximum air flow as a separate parameter, just do on an optimum point; optimum volume rate balancing it against more familiar metrics such as efficiency, power and noise. The way that ebm-papst has been employed to create the Axiblade generation.

6. AxiBlade’s degree of protection is IP 55

5, the first digit is related to solids: Protected from limited dust ingress.

5, the second digit is related to liquids: Protected from low-pressure water jets from any direction.

7. AxiBlade’s environmental protection class is H2:

H2 testing goes far beyond the requirements of the IP protection classes.

ebm-papst has taken the environmental conditions of an operating fan into account early on, as your requirements are more than IP classes (to find out more read the “Environmental Protection classes” handout)